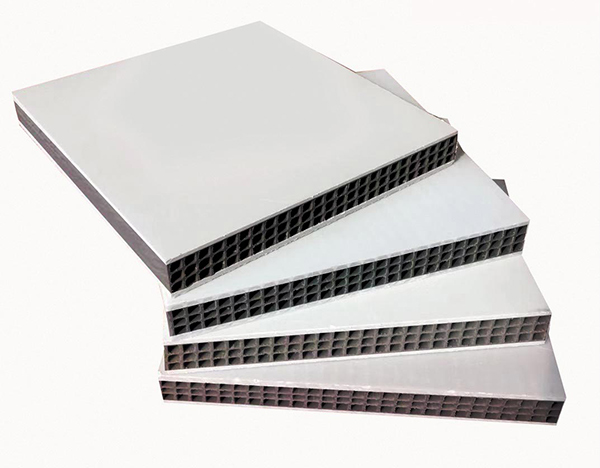

TCT - PP HOLLOW PLASTIC FORMWORK, is a Shuttering board of an eco-friendly and energy-efficient product made of Polyprone (PP) product. Tuffcell construction Template (TCT) is a brand of our Shuttering Formwork for an environment friendly product.

Tuffcell construction Template (TCT), a brand of our Shuttering Formwork is generally made of environmentally friendly non-polluting and recoverable polypropylene (PP). It is a high-tech, comprehensive performance, energy-saving and environmentally-friendly plastic sheet, which is a plastic building material commonly used in the world. TCT can easily replace the traditional wood formwork, composite steel formwork, bamboo-wood bonding formwork and all-steel large formwork.

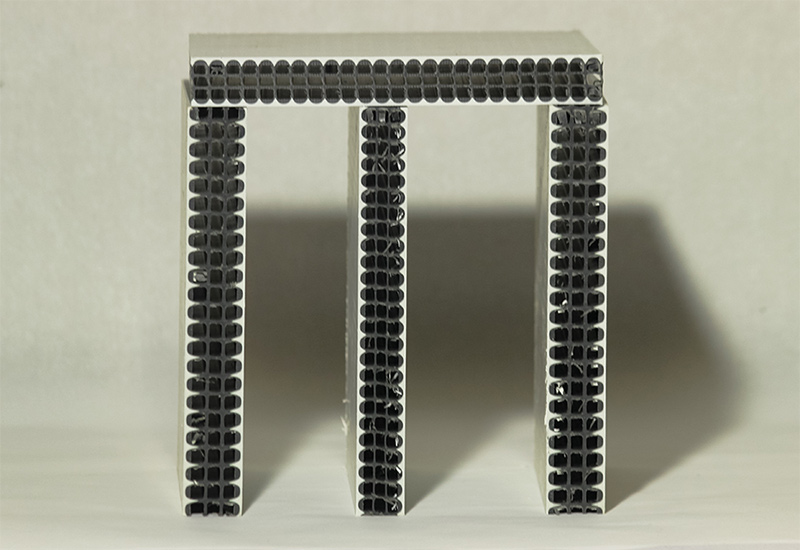

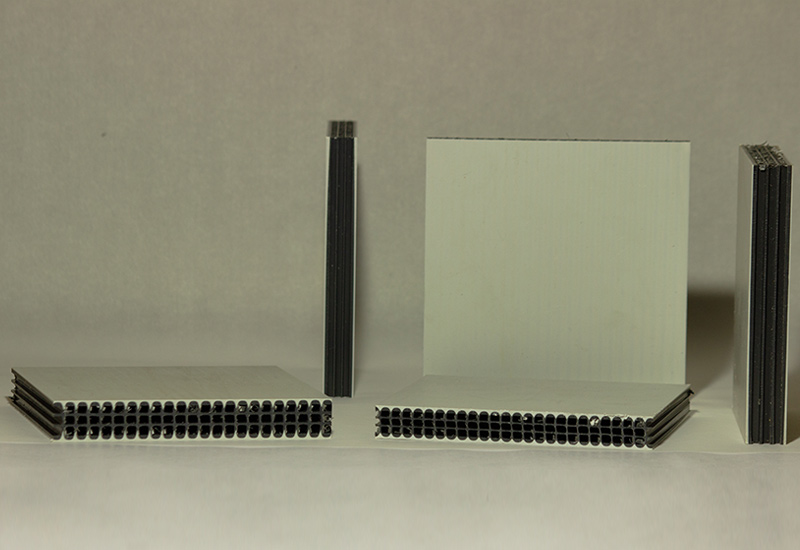

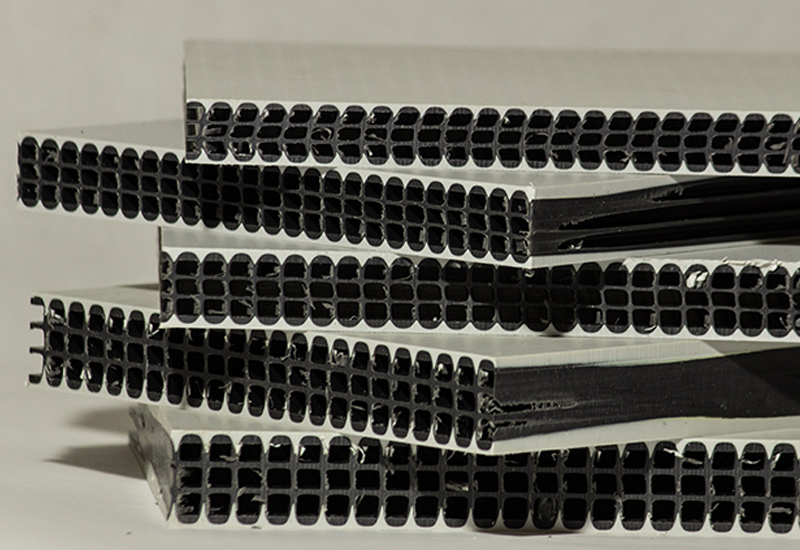

TUFFCELL CONSTRUCTION TEMPLATE is resistant to water and heat which makes it strong and light compared to wood or metal. We can meet the thickness or strength you for your specific situation. PP Hollow formwork is specially processed on surface. This kind of formwork has a stronger & smooth surface, it can be easily released and it for can bear higher temperature like above 45°C for recycling process. TCT Formwork can be kept stable and smooth in hot weather and seasons. It has no absorption of moisture, no deformation, no mildew. So, you can easily count on them to use in different environment and underground.

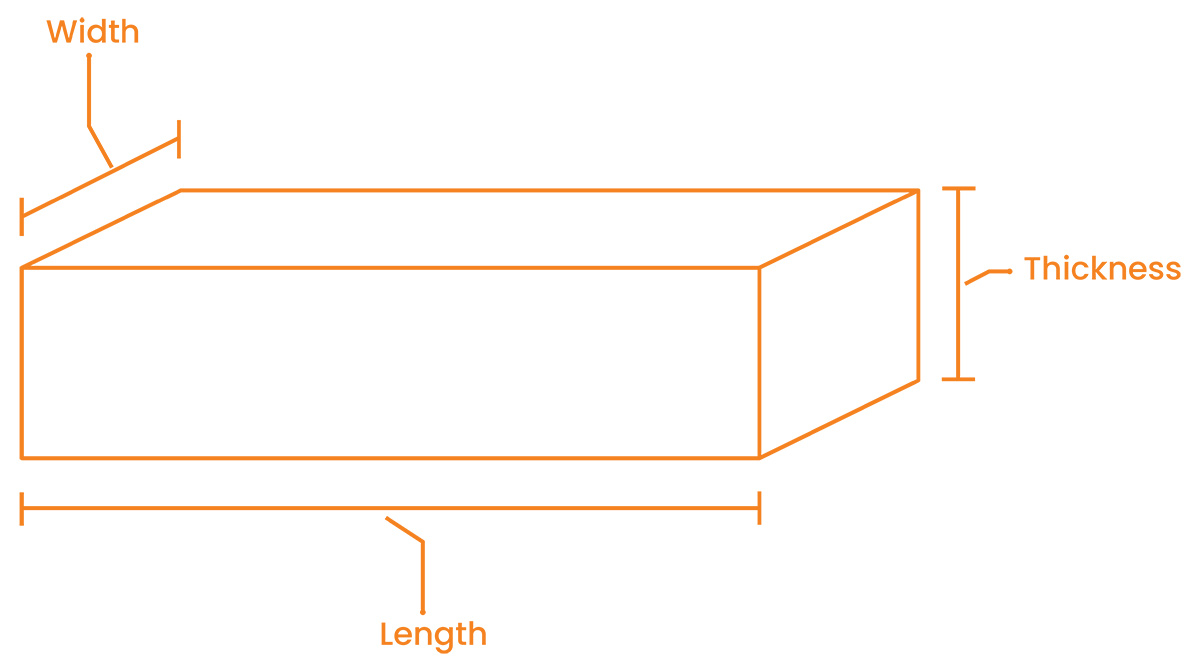

Size |

Thickness |

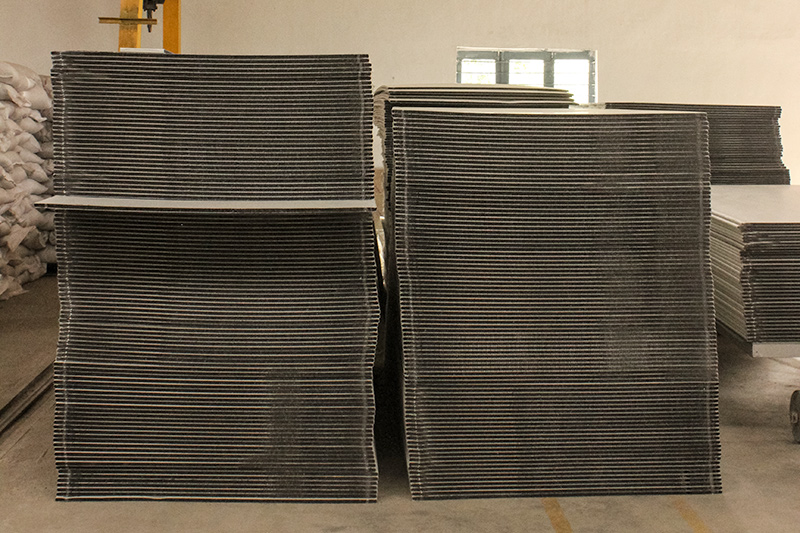

Qty / Pallet |

Weight / PC |

Qty / 20ft |

Qty / 40ft |

1220*2440mm |

12mm |

70pcs |

23 kg |

560pcs |

1120pcs |

1220*2440mm |

15mm |

54pcs |

27 kg |

432pcs |

1026pcs |

1220*2440mm |

18mm |

50pcs |

32 kg |

400pcs |

850pcs |

Available Thickness : 12-200mm, Max Length 30000mm, Max Width - 1250mm |

|||||

PP Hollow construction formwork Form provides the contractor with a rapid and cost effective method of constructing on site. Manufactured from heavy duty polypropylene in 12mm - 18mm thickness, Corrugated Beam Form offers many advantages over traditional formwork. Plastic formwork is a new product to replace wood formwork, composite steel formwork, bamboo-wood bonding formwork and all-steel large formwork. Durable, easy to manage, Improve the speed, efficiency and quality of your foundation work. There’s no need to use chemicals such as mould oils, and you’re spending less time removing shuttering. It also requires minimal skill input from ground workers, significantly improving efficiency all-round.

| Dimensions | 4 * 8 FT |

| Colors | White and Grey |

| Thickness | 12 and 15 mm |

The times of reuse can reach more than 60 times, long service life.

PP hollow board doesn’t absorb water and does not require special care or storage.

Surface and finish of product is smooth, bright and clean. Casting moulding effect is good. No plaster is needed. Portable and easy to install.

as more turnover times 60 or more, no oil or agent expense, its gives you low costing.Light weight Manual operation, no crane required. reduce 20% labour cost than plywood

high strength, high hardness, impact resistance, wear resistance.

No need brushing release agent, only tapping, formwork will fall off. Removing is convenient, quick and safe. Short working hours and speed up the construction schedule efficiently.

the type and specification can be customised according to the requirement of construction project.

Environmental protection and energy saving, no pollution. It’s a green product.

Waste produce can be recycled and reprocessed, making full use of waste materials. This property can greatly reduce the project cost. Compared with wooden and steel formwork.

High mechanical Strength-Easy to process, Sawing and nailing can be done. Acid and alkaline resistance, corrosion resistance, no cracking, no deformation, no absorption and size stability.TCT can be combined vertically and horizontally optionally.

| PERFORMANCE | TCT | MODULAR PLASTIC FOAM WORK | PVC PLASTIC FOAM WORK | PLYWOOD | BAMBOO PLYWOOD | METAL FOAM WORK |

| Water resistance | Good | Good | No | No | No | No |

| Corrosion resistance | Good | Good | No | No | No | No |

| Tenacity | Good | Bad | - | - | - | - |

| Impact strength | High | Easily broken | Normal | Poor | Poor | High |

| After absorbing water | No deformed | No deformed | Deformed | Deformed | Deformed | Deformed |

| Release agent | No need | No need | Need | Need | Need | No |

| Wrap used | No | No | Yes | Yes | Yes | No |

| Weight(kg/sq) | 7.75 | 10 | 15 | 7.2 | 7.5 | - |

| Recylce | - | - | - | |||

| Bearing capacity | High | Bad | Normal | Normal | Normal | Hard |

| Eco friendly | - | - | - | |||

| Cost of use | Low | Higher | High | Higher | Higher | Higher |

| Reusable time | Over 60 | Over 60 | 20-30 | 3-6 | 6-8 | 100 |

We Design Our Products As Per The International Standards. We are also into exporting to countries like Thailand, Indonesia, UAE, Kuwait, South Africa, Sudan, Saudi and other more. Our port is FOB Mundra and the delivery time is about 20-30 working days.